Comprehensive Guide to Plastic Product Design

Plastic product design optimizes processing methods, materials, and production volumes for effective, durable, and attractive products.

This guide explores the essential elements of plastic product design and provides insights into various manufacturing methods and design considerations.

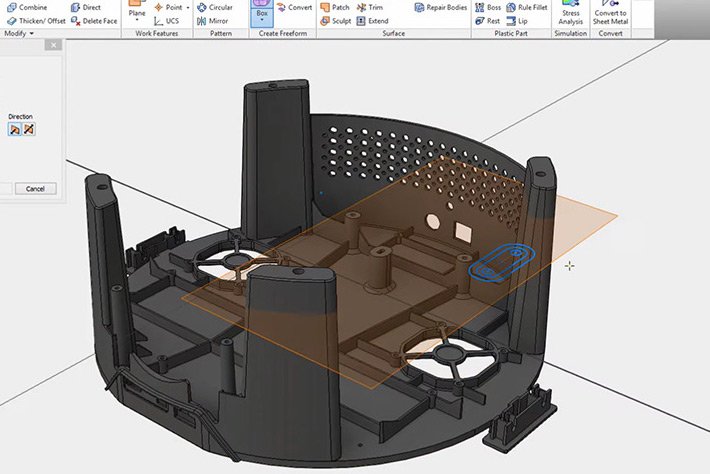

When starting a plastic product design, it’s crucial to choose the appropriate processing method. Different methods cater to different needs, from small-scale hobbyist projects to large industrial productions. Understanding these methods will help you make informed decisions.

Casting is suitable for creating solid items using silicon molds and thermoset plastics. It is ideal for both hobbyists and industrial applications requiring thick sections of thermoplastics, such as bulletproof glass. This method allows for in-mold polymerization to produce fiber-reinforced objects with multiple layers.

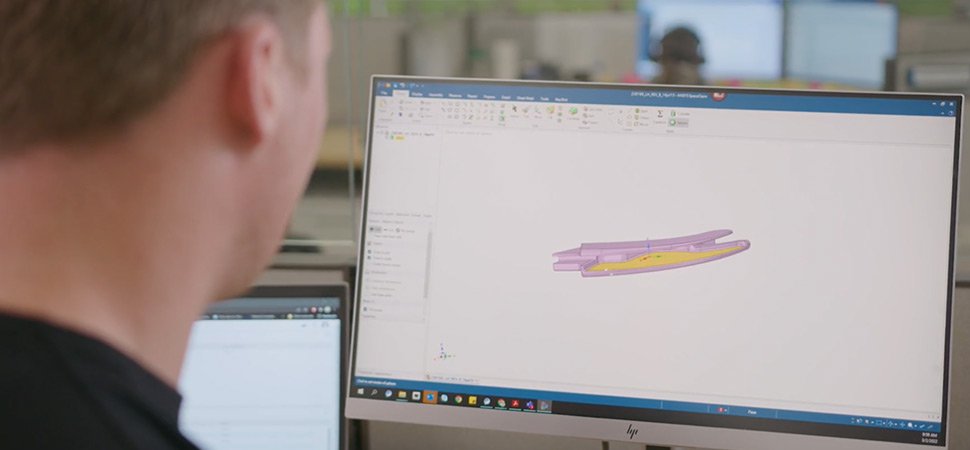

3D printing offers versatility and precision for low-volume production and prototyping. It is widely used by hobbyists and professionals to create various plastic items and models, facilitating design evaluation and iterative development.

Thermoforming is ideal for producing simple shapes from thermoplastic sheets, commonly used in disposable packaging and dishes. This method is effective for both small-scale and high-volume production, making it a popular choice for businesses and hobbyists alike.

Laying up is used to create large, reinforced objects such as boat hulls, vehicle bodies, and wind turbine blades. This method involves using molds and thermoset plastics to produce strong and durable products, suitable for heavy-duty applications.

Plastic product design optimizes processing methods, materials, and production volumes for effective, durable, and attractive products.

This guide delves into the world of plastic product design, comparing 3D printing and injection molding.

Discover the latest trends and techniques in creating cutting-edge plastic products.

Adorn your blog post listing section with standard blog post listing that comes with less focused buttons

Plastic product design optimizes processing methods, materials, and production volumes for effective, durable, and attractive products.

This guide delves into the world of plastic product design, comparing 3D printing and injection molding.

0086-18057179052

info@plasticssolution.com

We will contact you within 1 working day, please pay attention to the email with the suffix “info@plasticssolution.com”.

Didn’t find what you want,

ask our leader for help directly!