- Home

- »

- Plastic Product Design

Plastic Product Design Solutions

We are the fastest and most custom plastic product design projects of high quality, on time and a minimum budget. Get your quote now.

Certifications

ISO 9001:2015 | ITAR Registered | Critical to Quality Inspections

One-Stop Plastic Product Design & Manufacturing

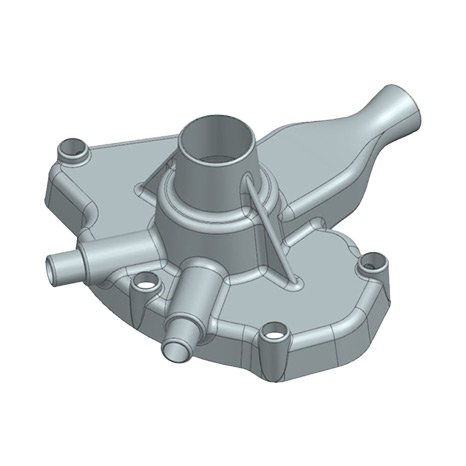

We specialize in comprehensive plastic product design and development solutions. From concept to manufacturing, we bring your ideas to life with innovative technology and precision. Our team seamlessly integrates design, engineering, and production to ensure the highest quality and functionality.

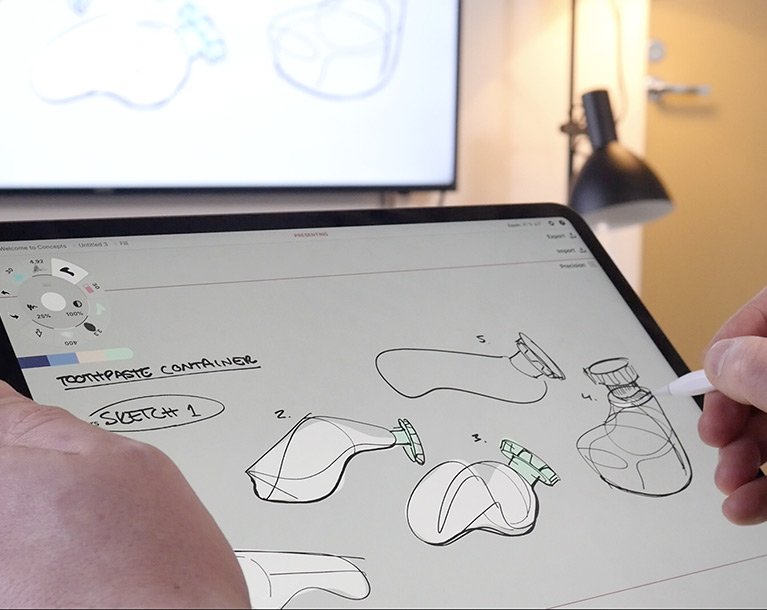

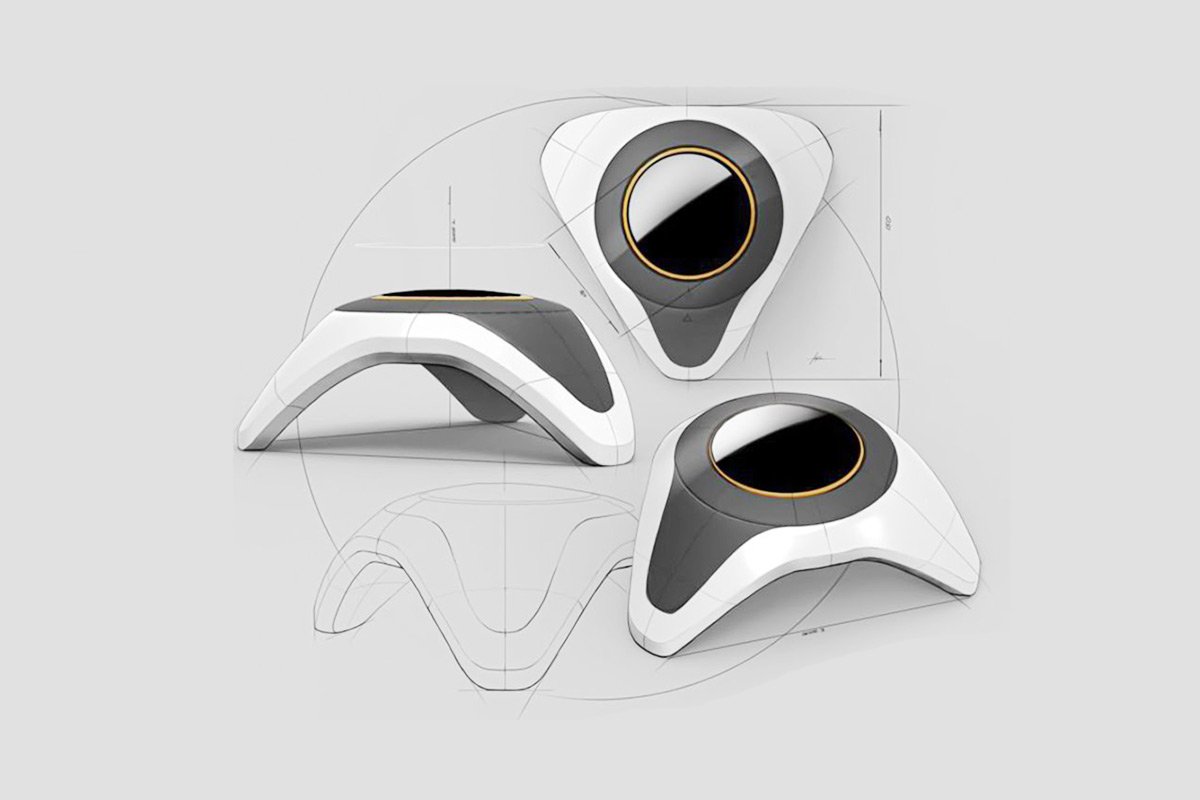

Product Concept Development

Starting from your idea, we provide CAD design, engineering, and FEA analysis, ensuring product functionality and durability through stress testing.

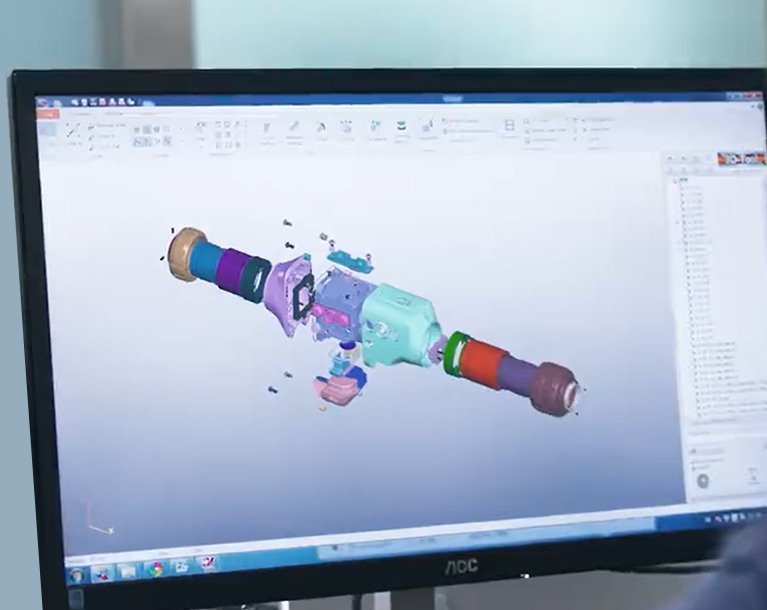

Design & Engineering

Our designers work with you to refine your product’s function and appearance, using 3D CAD, FEA analysis, and stress testing to ensure performance and manufacturability.

Rapid Prototyping & Testing

We use rapid prototyping, including 3D printing and CNC machining, to quickly create prototype parts, helping evaluate design before moving to full-scale production.

Full Manufacturing & Processing

After finalizing product design, we handle mold manufacturing, CNC machining, and injection molding. Services like screen printing, anodizing, and assembly ensure market-ready, high-quality finishes.

Get an online quote and custom plastic products design analysis today.

- Design Price

- Design Revisions

- Prototype Turnaround

- Design Support

- Material Options

- Additional Features

The design cost for plastic product development can vary significantly based on the complexity, functionality, and scale of the project. Typically, we offer competitive pricing options designed to meet the needs of both startups and large-scale manufacturers. Design prices are influenced by factors such as:

- Number of parts in the design.

- Complexity of geometry and engineering analysis.

- Customization requirements, including additional features or intricate detailing. We offer clear and upfront pricing with no hidden costs, ensuring you have full visibility into your investment.

We offer unlimited design revisions within a predefined project scope to ensure you get the exact product you envision. Our design revisions are:

- Collaborative, allowing clients to review prototypes and provide feedback.

- Flexible, so changes in the design can be made as needed before moving into production.

- Rapid, with quick turnaround on revisions, helping to keep the design process efficient and agile. Our goal is to perfect your design while keeping the process streamlined.

Speed is critical in the prototyping phase. We offer fast prototype turnaround times, typically ranging from:

- 24 hours to 3 days, depending on complexity and material selection.

- Priority options for urgent projects, with express services available for prototypes in as fast as 1 day. By utilizing advanced technologies like 3D printing, CNC machining, and vacuum casting, we ensure that your prototype is delivered on time and meets the exact specifications for further testing and review.

Our design support team provides end-to-end assistance throughout the plastic product design process:

- Expert consultations with our engineers to optimize designs for manufacturability and performance.

- Material and structure advice, ensuring the design is aligned with your project’s functional and aesthetic goals.

- Ongoing communication, with dedicated support available 24/7 to handle any queries or changes you may have during the design phase. Our design support is tailored to your specific project needs, ensuring you have a reliable partner every step of the way.

We offer an extensive range of material options for plastic product design, including:

- Thermoplastics: ABS, Nylon, Polycarbonate, PP, and more.

- Thermosets: Epoxy resins, silicone rubber, and others.

- High-performance plastics: PEEK, PEI for extreme environments and high-strength applications. Our experts guide you through the material selection process to ensure you choose the right material based on factors like strength, durability, flexibility, cost, and environmental resistance.

Beyond core services, we offer various additional features to enhance the product design and development experience:

- Finishing options such as polishing, painting, and coating to give your prototypes or products the desired look and feel.

- Tolerances of ±0.001-0.003 in., ensuring high precision for intricate designs.

- Design for Manufacturing (DFM) analysis, helping you optimize your design for efficient production and cost reduction.

- Documentation and reporting, including design validation reports, material certifications, and quality assurance checks.

Why Use Our Plastic Product Design Solutions?

We focus on ease of production, reliable quality, and cost-efficiency, ensuring that our clients’ projects meet high standards,are completed on time, and stay within budget.

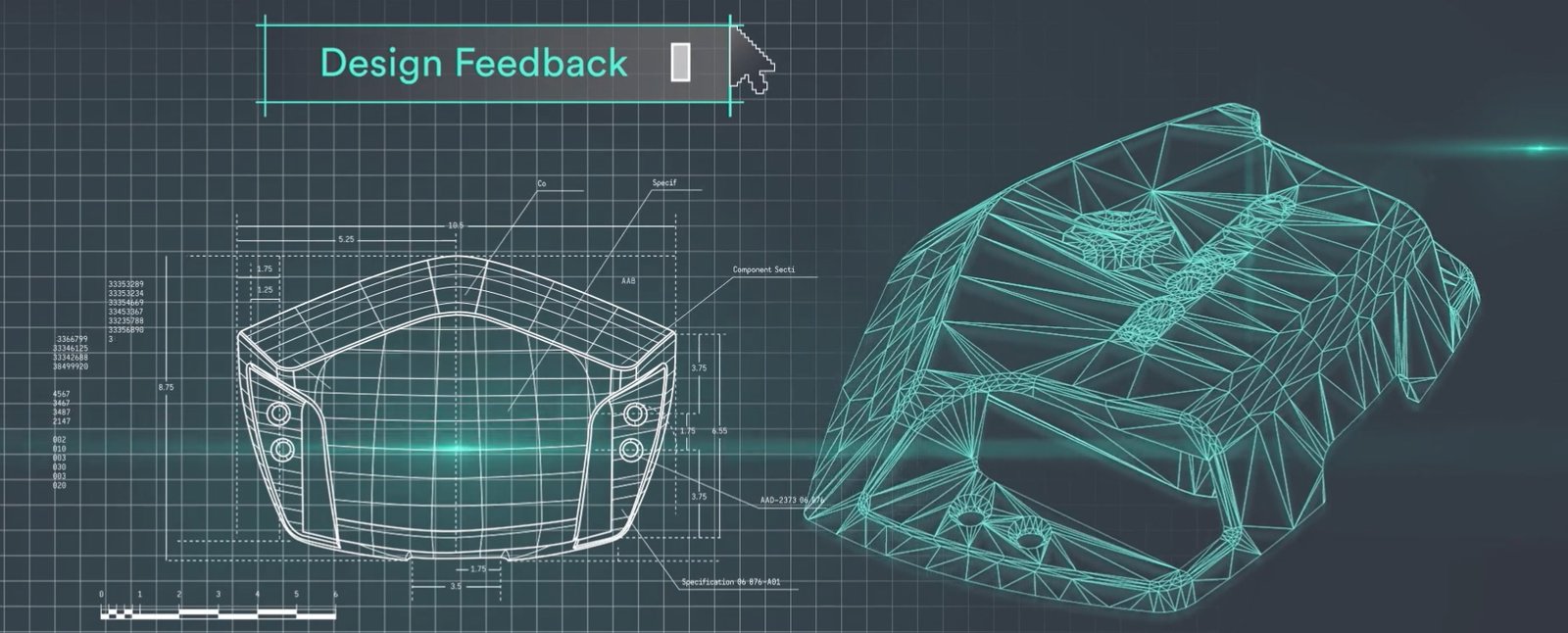

Design Feedback

- Get real-time design feedback to ensure manufacturability, enabling early adjustments before the prototyping phase.

- Collaborate with our engineers to solve any design or manufacturing challenges before moving to production.

Iterative Development

- Rapidly receive physical prototypes to modify and enhance designs during early development.

- Test and iterate multiple design versions simultaneously to streamline the product development cycle and accelerate time to market.

Design Validation

- Test prototypes for form, fit, and function with production-grade materials.

- Use small prototype runs to validate product performance and refine designs before large-scale production.

Manufacturing Optimization

- Design for ease of production, ensuring the final product is cost-effective, reliable, and ready for full-scale manufacturing.

- Utilize our expertise in mold manufacturing and injection molding to streamline your transition from design to market.

Design

Our Recent Success Projects

Our team specializes in turning innovative ideas into tangible plastic products.

We offer a comprehensive range of services, from initial design

consultations to on-demand manufacturing.

Eco-friendly Series

Daily Life Series

Game Series

Outdoor lighting series

Medicine packaging series

Kitchen Storage Series

FAQs for Plastic Product Design Solutions

Simply contact us with your idea or project requirements, and we will provide an initial consultation and quote to kickstart the design process.

Plastic product design refers to the process of creating and developing products made from plastic materials. It involves both aesthetic and functional aspects, ensuring that the final product meets specific customer needs and industry requirements. This process typically includes concept creation, CAD modeling, material selection, and design validation.

Key factors include:

Material selection: Choosing the right type of plastic (thermoplastics or thermosetting plastics) based on durability, flexibility, and application.

Moldability: Ensuring the design can be efficiently produced using injection molding or other manufacturing processes.

Structural integrity: Designing for strength, durability, and performance under various conditions.

Cost efficiency: Optimizing the design to reduce production and material costs without sacrificing quality.

Common software tools include:

CAD (Computer-Aided Design): Programs like SolidWorks, AutoCAD, and CATIA for 3D modeling and design.

CAE (Computer-Aided Engineering): Tools like Moldflow for simulating the moldability of the product.

FEA (Finite Element Analysis): Software such as ANSYS to analyze stress, strain, and thermal properties.

We work with a wide range of plastic materials, including ABS, PP, PVC, and eco-friendly plastics like PLA and recycled polymers.

We provide end-to-end services, including product concept development, CAD design, engineering, prototyping, and full-scale manufacturing.

We conduct stress testing, heat resistance tests, and form validation to ensure the product meets industry standards and client expectations.

Common quality assurance methods include:

First Article Inspection (FAI): Ensuring the first produced part matches the design specifications.

Dimensional analysis: Verifying that the parts are produced within the specified tolerances.

Functional testing: Confirming that the product performs as required under operating conditions.

Current trends include:

Sustainability: Increased use of biodegradable and recycled plastics.

Lightweighting: Designing parts that use less material without compromising strength.

Smart materials: Incorporation of plastics that respond to environmental stimuli (e.g., heat, light).

Yes, we work closely with you to refine your design, offering suggestions to improve functionality, aesthetics, and manufacturability.

We serve various industries, including automotive, electronics, consumer goods, medical, and industrial products, among others.

Our MOQ depends on the specific project, but we are flexible and can accommodate both small and large production runs.

Yes, we offer multiple design revisions during the development phase to ensure the final product meets your expectations.

Choosing the right plastic depends on:

Application: What the product will be used for.

Environmental factors: Will it be exposed to heat, UV light, or chemicals?

Cost: Balancing performance with affordability.

Mechanical properties: Desired strength, flexibility, and durability.

Prototyping helps:

Validate design: Ensures the product meets functional and aesthetic expectations.

Test materials: Helps in selecting the right material for performance and cost-efficiency.

Identify flaws: Detects design issues early to avoid costly revisions during mass production.

DFM ensures that the design can be manufactured easily and cost-effectively, considering factors like mold design, part complexity, and material flow in the mold. It reduces production delays and ensures the final product meets quality standards.

The duration depends on the complexity of the design and the manufacturing process. Simple designs can take 1~2 weeks, while more complex products with detailed prototyping and testing might take several months.

Yes, we provide rapid prototyping using 3D printing, CNC machining, and other methods to create functional prototypes in as little as 7 days.

Our standard prototype turnaround time is 3–7 days, depending on the complexity of the design and materials used.

Yes, we offer a one-stop solution from concept development to manufacturing, ensuring a seamless transition from design to production.

Absolutely! We prioritize DFM to ensure your product can be efficiently manufactured, reducing costs and improving production speed.

Yes, we specialize in custom plastic product design and manufacturing tailored to your specific needs and requirements.

Lead times depend on the complexity and volume of the order. Typically, production can take 2–6 weeks after the design is finalized.

Yes, we offer secondary processing services such as screen printing, painting, electroplating, and product assembly.