Comprehensive Guide to Plastic Product Design

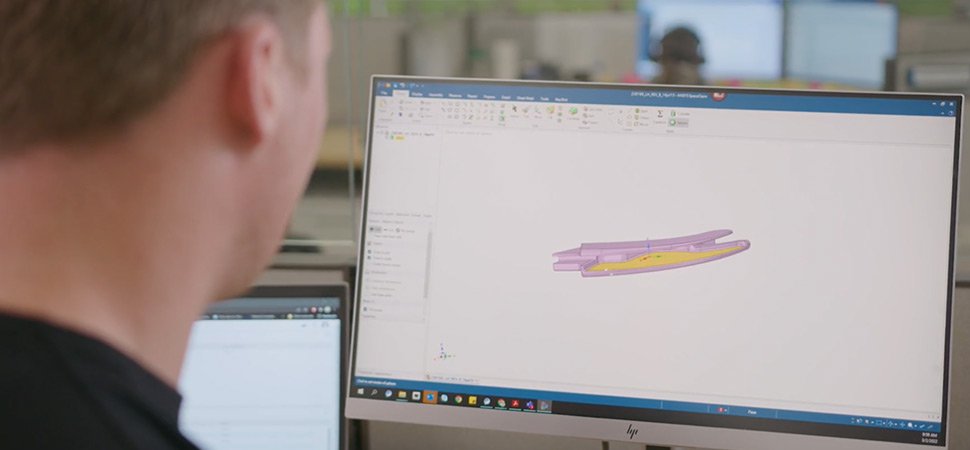

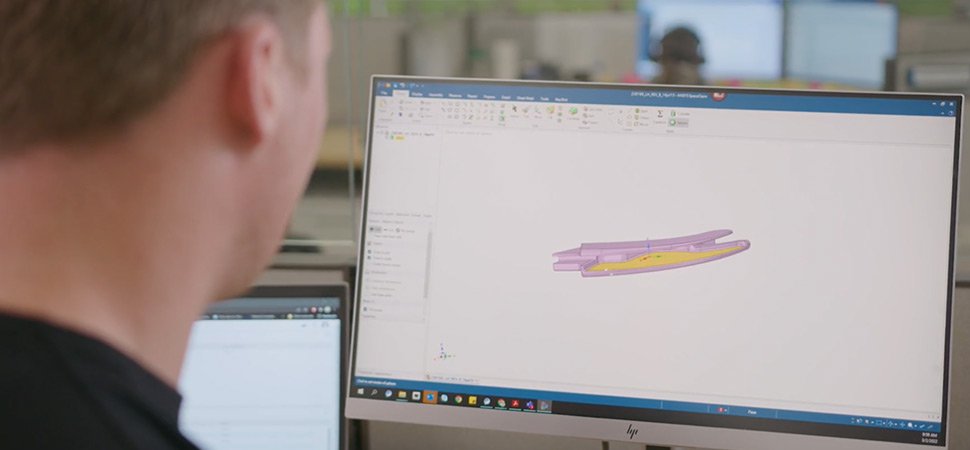

Plastic product design optimizes processing methods, materials, and production volumes for effective, durable, and attractive products.

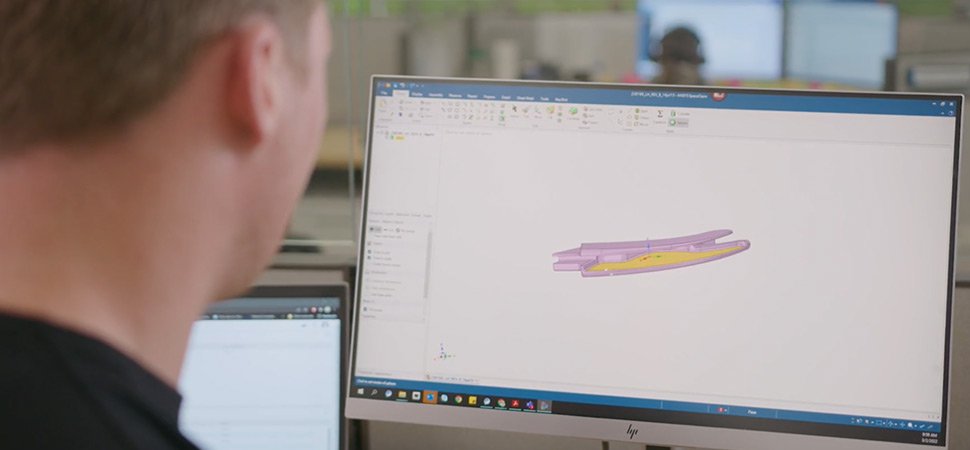

The landscape of manufacturing is rapidly evolving with the advent of new materials, technologies, and processes. Among these, 3D printing and injection molding are two prominent methods that serve distinct purposes. While 3D printing excels in prototyping and custom parts, injection molding remains the go-to for high-volume production. This guide will help you understand the cost drivers and applications of both technologies to make informed decisions for your business.

Build time and post-processing are two main cost drivers for 3D printing. A longer build time means a more expensive part. For example, printing a solid cube would take more time and cost more than a hollow design. Additionally, required support structures during the printing process increase machine time and cost.

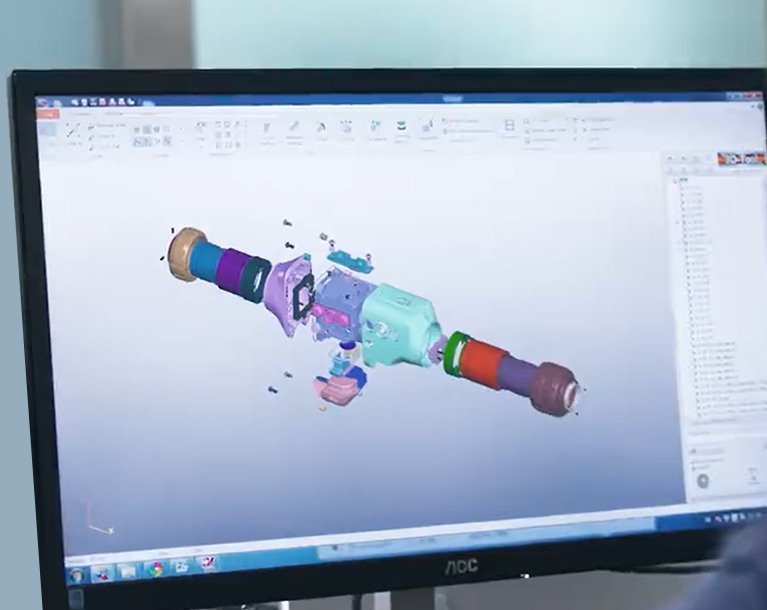

For injection molding, part complexity and mold design are significant cost drivers. Design for manufacturability (DFM) analysis is crucial to identify modifications that reduce cost. Complex parts may require more expensive molds, and any necessary cam or insert can increase overall mold size and cost.

Depending on the technology, 3D printing materials can add significant expense. Some processes, like direct metal laser sintering (DMLS), recycle unused powder, whereas others, like selective laser sintering (SLS), do not, driving up costs.

Injection molding offers more than 100 thermoplastic and thermoset materials that eject from the mold with high-quality finishes. These materials are generally more cost-effective, especially at higher volumes.

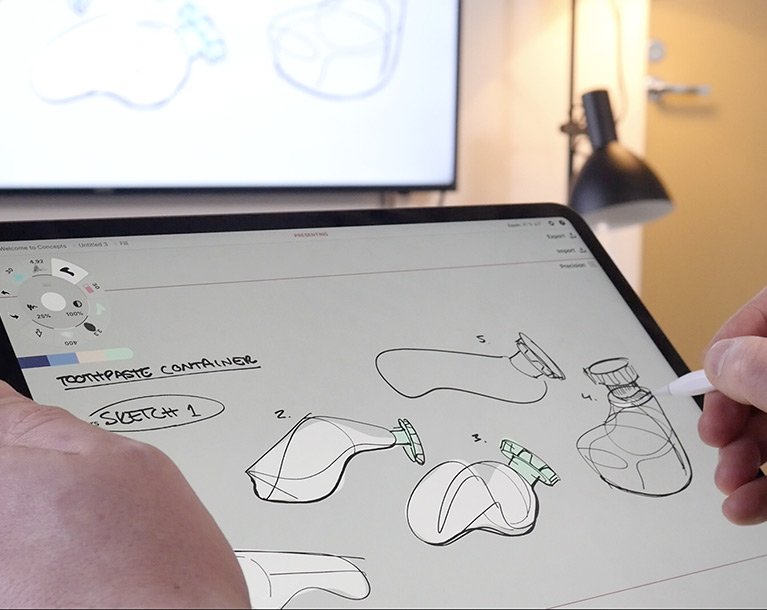

Product iteration with 3D printing is faster and less expensive compared to injection molding. Design flaws can be easily tweaked and reprinted quickly. This makes 3D printing ideal for rapid prototyping and short-run production.

Injection molding requires significant upfront design work. Any changes to the mold design are costly and time-consuming, making this method better suited for final production once the design is perfected.

3D printing does not require investment in setup or tooling costs. This makes it a flexible and cost-effective option for low-volume production and prototyping.

Injection molding comes with tooling costs and often a setup fee with each run of molded parts. However, once the mold is created, the cost per part decreases significantly with higher volumes.

3D printing is more expensive per piece at higher volumes due to longer build times and post-processing requirements. It is best suited for low-volume production and complex, custom parts.

Injection molding shines in high-volume production, where the piece-part price is significantly lower compared to 3D printing. The initial tooling investment is offset by the reduced cost per part in large quantities.

Nearly all 3D-printed parts require some level of post-processing, such as removing support structures or improving cosmetic appearance. These processes add to the overall cost but are necessary for part quality.

Injection-molded parts typically require less post-processing, as they can be designed to eject from the mold with high-quality finishes. Additional finishing processes are available but are not necessary for durability and appearance.

3D printing is ideal for prototyping due to its flexibility and low upfront costs. It allows for quick iterations and design changes, making it perfect for developing new products.

Injection molding is still viable at the prototyping stage, especially when using a single-cavity aluminum mold. For on-demand manufacturing, injection molding offers supply chain flexibility and cost savings for high-volume production.

Choosing between 3D printing and injection molding depends on your specific needs and production volumes. 3D printing is excellent for prototyping and low-volume, custom parts, while injection molding is the go-to for cost-effective, high-volume production. Understanding the cost drivers and applications of each technology will help you make the best decision for your manufacturing needs.

Plastic product design optimizes processing methods, materials, and production volumes for effective, durable, and attractive products.

This guide delves into the world of plastic product design, comparing 3D printing and injection molding.

Discover the latest trends and techniques in creating cutting-edge plastic products.

Adorn your blog post listing section with standard blog post listing that comes with less focused buttons

Plastic product design optimizes processing methods, materials, and production volumes for effective, durable, and attractive products.

This guide delves into the world of plastic product design, comparing 3D printing and injection molding.

0086-18057179052

info@plasticssolution.com

We will contact you within 1 working day, please pay attention to the email with the suffix “info@plasticssolution.com”.

Didn’t find what you want,

ask our leader for help directly!