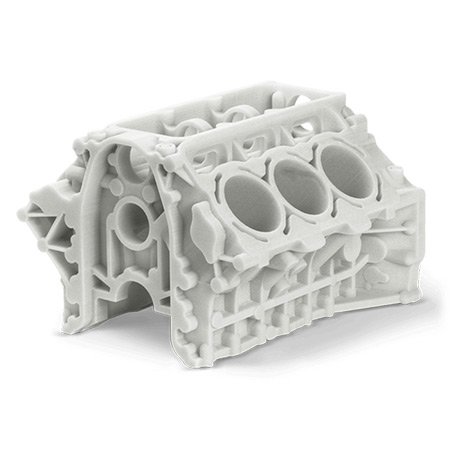

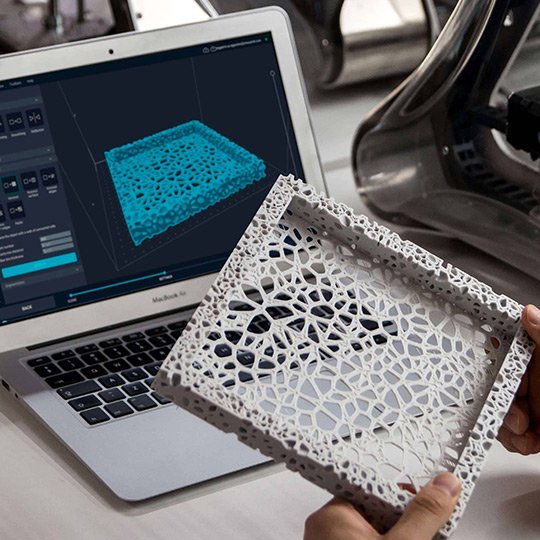

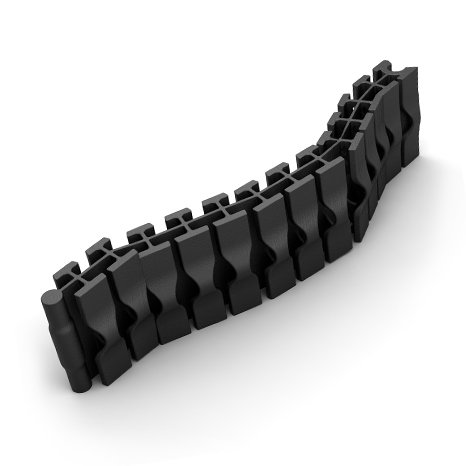

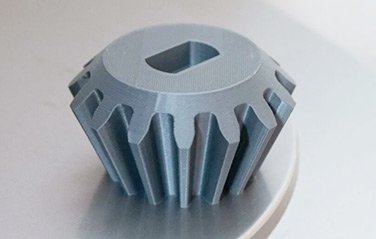

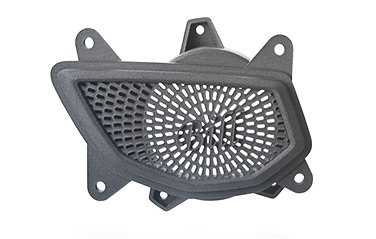

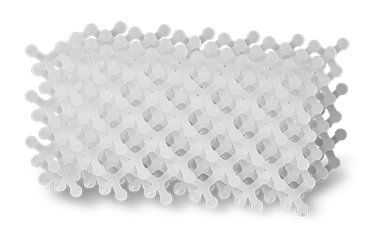

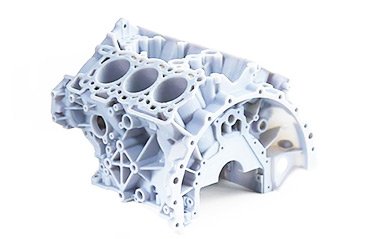

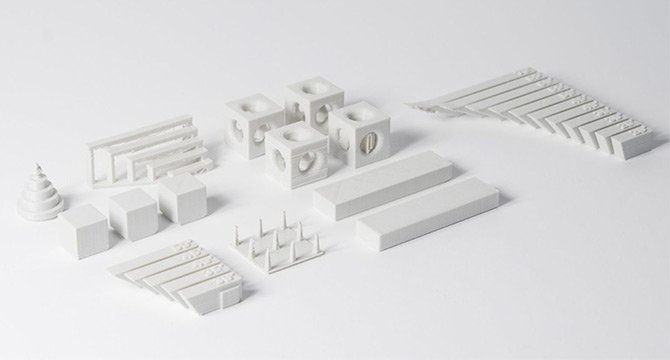

FDM 3D Printing for Functional Prototypes

Our Fused Deposition Modeling (FDM) 3D printing service builds strong, functional parts by heating and extruding thermoplastics layer by layer. FDM is ideal for durable prototypes and end-use components, with material options such as ABS, TPU, PEI, and PETG for added versatility.